Cleaning of Machining Equipment and Fluids

Deep Cleaning and Complete Machine Care

We are equipped for thorough deep cleaning and full maintenance of both machines and their fluids. Our experienced team of technicians not only cleans the tanks but also removes covers and cleans critical components — drainage channels, linear guides, drives, motors, and pumps.

As mechanical engineers, we understand all machine brands and models.

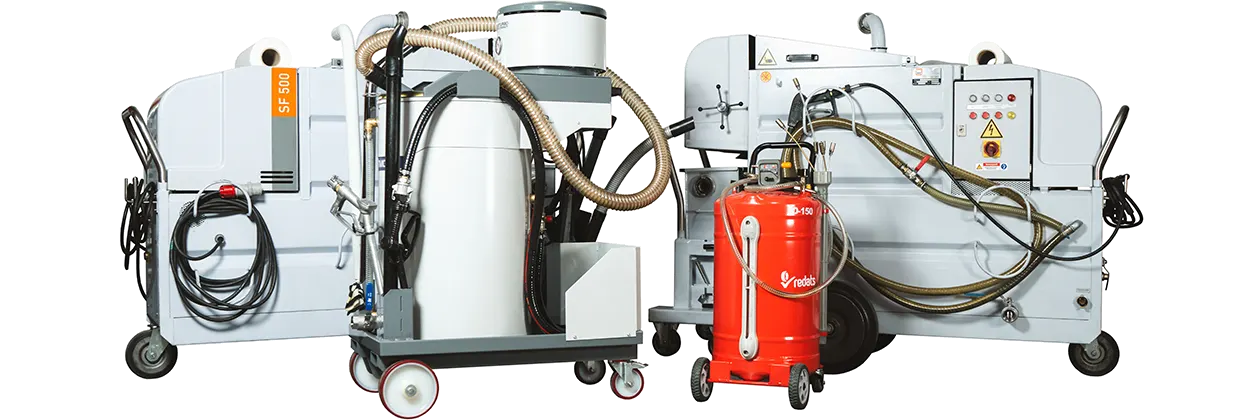

For our work, we use state-of-the-art equipment, including the MKR SF 500 cleaning system with a specially modified 500-liter vacuum unit, capable of completely draining the machine tank.

An integrated high-pressure pump cleans the machine interior using filtered emulsion, and with the help of professional agents, we fine-tune the machine for maximum performance.

Extending the Life of Machining Fluids

We clean all types of machining fluids, degreasing bath water, cutting and hydraulic oils, and many other industrial liquids.

We use proven cleaning and disinfecting agents and continuously improve our methods and services.

We tailor the entire maintenance process for your machines and fluids to your specific production and operational needs.

Write to us or schedule a free, non-binding consultation.

Frequently Asked Questions

What makes our solution better?

Traditionally, machine operators clean their own machines. We are faster, more efficient, and the best-equipped company in the Czech Republic. Moreover, we are engineers who know every screw of every machine on the market. This means significantly shorter downtimes — saving your company both time and money.

What types of fluids can you clean?

We clean all types of machining fluids, degreasing bath water, cutting oils, hydraulic oils, and many other industrial liquids and oils.

How often should the emulsion in the tank be replaced?

Emulsion — a mixture of water and oil — has a lifespan determined by its use and wear. After a certain time, it may cause machine damage or affect machined parts. Typically, the replacement period is a few months, with one year being the maximum limit.

Using our filtration and separation systems, this interval can be extended up to four times.

What happens to the emulsions you remove from the tanks?

We cooperate with certified partners who dispose of emulsions and other fluids safely and environmentally. This allows us to provide customers with a complete service — from cleaning the machine to the eco-friendly disposal of waste fluids.